Modix

Modix BIG-180X V4 3D Printer

Modix BIG-180X V4 3D Printer

Share

PLEASE NOTE: SPECIAL ORDER DELIVERY - 6-12 week delivery timeframe

Modix BIG-180X 3D printer was first introduced in late 2019. Similar to BIG-60, it has all the latest components of Generation 4 and enjoys the same level of modular offering to better match your needs and budget.

BIG-180X Specifications:

Here are a few of the BIG-180X unique specifications:

- Print Volume: 1,800 x 600 x 600mm (XYZ)

- Printer Dimensions: 2,630 x 1,060 x 1,573mm

- Machine Size (WxDxH): 2,630×1,060×1,573mm

- Shipping Weight: 210kg

- Build it yourself: self assembly kit

- Print Head: single Griffin extruder, 1.75mm filament

- IDEX: Secondary print head – Available on 3 models

- Stock with IDEX

- Recommended

- Kitchen Sink

- Duet3D Wifi 32 bit controller & Duex5 Expansion board

- 4 X Z axis motors are controlled individually providing automatic bed tilt calibration

- 100 probing point for automatic bed leveling

- Minimal Electricity requirements – single phase, 208-240V:

- EU/AU/UK customers: IEC 309 32A Blue (2P+E) outlet

- Price includes 12 months of warranty and lifetime support. Warranty does not include degradable (PEI sheet and nozzles) and consumables. Warranty can be extended up to two additional years

- Enclosure: included

- Z Axis Guides: Hiwin Rails included

- DUEX Expansion Board: Included

- Tilt Screen & Emergency Button: Optional

- Casters: Included

Chassis & Enclosure

- Solid 40X40 T-slot aluminum profiles

- Powder coated laser cut aluminum brackets and joints

- Enclosure – Closed enclosure made of 3mm black Aluminum Composite Panels (ACP). Enclosure is an optional add-on for BIG-60, BIG-120X & BIG-120Z and a default option for BIG-Meter and BIG-180X

Electronic Controller

Duet 2 WiFi, a powerful 3D Printer controller made in the UK. Duet is a well known and widely supported electronic platform for professional 3D printers. It is made by a respectful company and it is a major factor in our ability to provide ongoing high level of quality and reliability:

- Powerful 32 Bit Processor

- Dedicated WiFi module with external antenna

- Quiet TMC2660 stepper drivers, up to 256 micro-stepping

- High speed USD card and support for a second external SD card if required

- Dual extruders controlled on the main board, up to 5 additional stepper motor drivers are controlled on the DUEX expansion board

- High Power Rating: Each stepper driver is capable of 2.8A motor current, currently limited in software to 2.4A

- Access the printer via a PC, tablet or smartphone on a local network

- Set up and control your printer through the web interface

Fully Automated Calibration

All our printers’ models are delivered with the electronic expansion board named Duex. This allows allocating a dedicated driver per each motor for both Z axis and X axis. As a result, Modix is now offering a full set of automated calibrations routines including:

- Bed tilting calibration

- Bed leveling

- Gantry alignment

- Z offset calibration

Interfaces

Touch Screen- 7-inch Duet3D touchscreen – integrated with the controller

Web Interface – WiFi web access for remote control from either mobile or PC allowing users to upload print files directly from their workstation

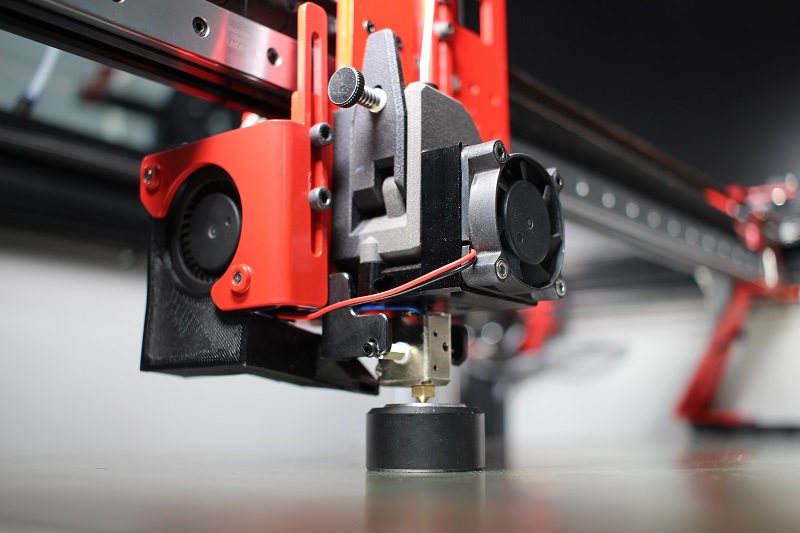

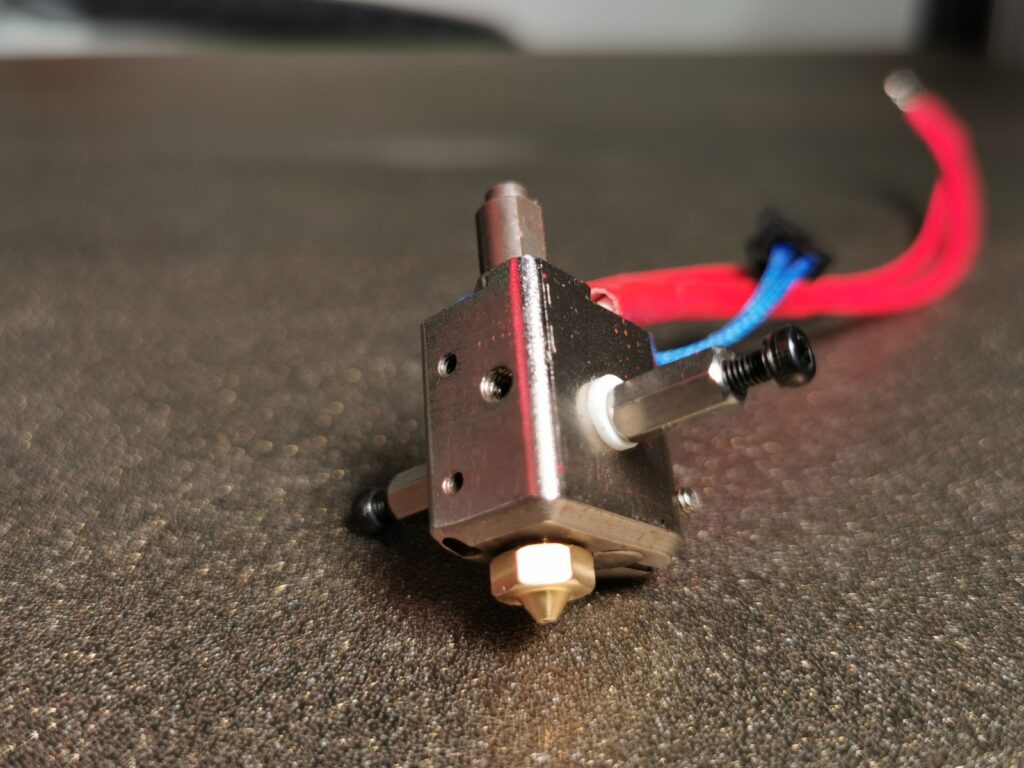

Griffin Print Head

Previously and optional upgrade and now is the default print head on all our printers, the new Griffin print-head is a major improvement to our offering. It consists of a custom extruder made by Bondtech (based on the BMG model) and of a new hotend designed by Modix. The new design comes default with every Modix printer and includes the following improvements:

High flow rate & high printing temperatures: The Bondtech extruder provides a double drive-gear system that grabs the filament from both sides. The heat-block is made of nickel-coated copper, for an increased rate of heat transfer and compatibility with higher printing temperatures. The design includes the advanced Slice Engineering Bi-Metal heat-break that extends the melting zone inside the heat-block by being mostly made of copper as well. In addition, an upgraded PT-1000 temperature sensor enables printing in higher temperatures of up to 500°c. The hotend components are rated for 500°c and so far have been verified with printing of up to 340°c.

Higher reliability: Large scale 3D printing usually involves the risk of the print-head scratching or crashing into the thick layer models resulting in bent or broken heat-breaks. The new print-head provides a rigid mounting of the heat-block, so it’s naturally more reliable and reduces these situations. The main reason for this is that the heat-block is now mounted on three faces instead of only one. It can withstand a much stronger impact thanks to this additional bracing. The longer-type Griffin High-Flow can also be attached to the rigid mounting as well.

Improved User Experience: The new print-head design makes nozzle replacements easier. The rigid mounting of the heat-block allows one handed nozzle replacement, making it even easier to change to different nozzle diameters.

Easy Swap: The design of the mounting bracket and the D shaft style of the Slice Engineering heat-break gives users the ability to replace the entire filament melting subsystem with ease. This will allow users to dedicate a complete setup for a specific filament type. i.e., keeping one setup for abrasive carbon filled filament and another for prototyping with PLA.

Compact Design: The new design maintains the previous design benefits of compact design that preserves the generous Z-axis travel and is compatible with the vast offering of E3D Volcano nozzles coming in numerous sizes and materials.

Smart: The new print-head allows automatic Z off-set calibration between the nozzle and the BL Touch probe. This is easier and more precise than the manual procedure. A dedicated sensor allows the BL-Touch and the nozzle to touch the surface, consequently. The precise relative distance between the probe and the nozzle (“Z-offset”) is saved automatically to the printer.

*The brass nozzle needs to be replaced with a higher-temperature capable nozzle as well for temperatures above 300c

Improved Generation 4 Offering

With generation 4, all Modix 3D printers are now shipped with the new Griffin print head, clog and crash detectors.

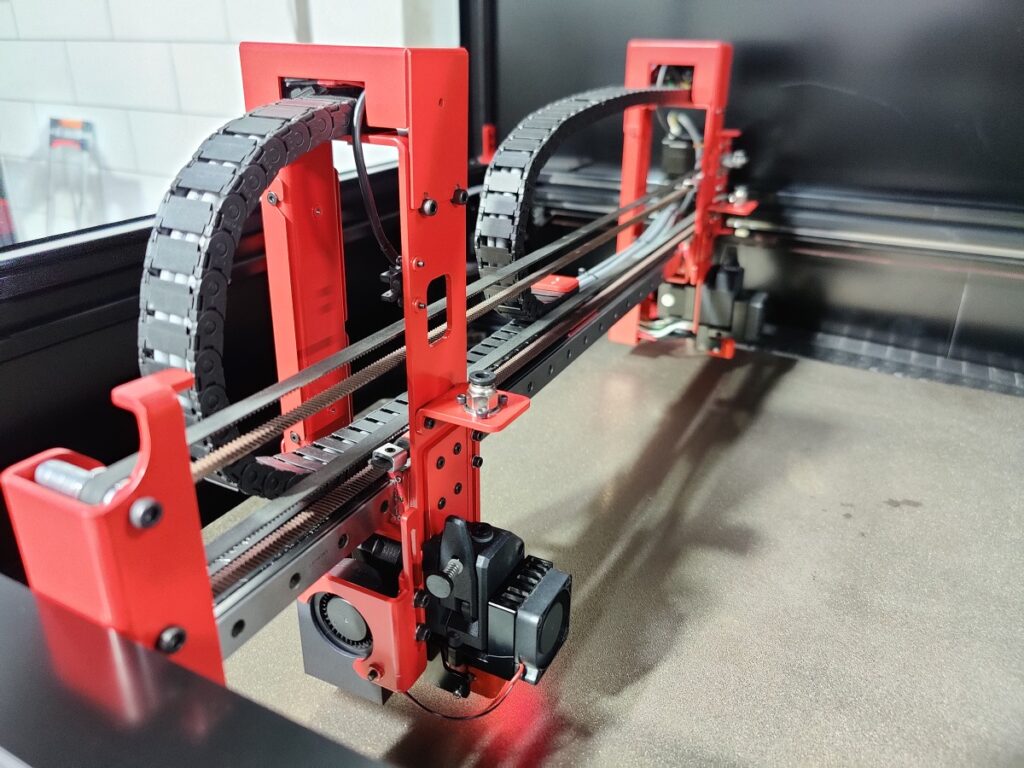

IDEX dual printing add-on

“IDEX” stands for independent dual extruder, where each extruder is capable of moving independently from each other. As a result, while the active extruder is printing, the second extruder is “parked” outside the printing area. Therefore, dual material printing made with IDEX technology comes out cleaner and with higher success ratios in comparison to other configurations as such the two print heads are installed side by side on the same carriage.

IDEX allows printing of advanced models that have internal geometries by using water-soluble filament. In addition, printing the dense support layers (interface layers between the model and the solid support structure) with a breakaway support filament, saves a lot of manual labor for support removal. In addition, since there is no need to keep air gap between the dense support and the model itself as normally happened when using the same material for support, the supported bottom surface of the models comes out clean and smooth. This saves a lot of time needed usually for sanding during the post process.

The IDEX is sold as an optional add-on for all generation 4 printers. includes:

- Secondary printing subsystem: Griffin print head, clog detector, PTFE, spool mount

- Motion system: secondary Y axis motor with the required components (belts, pulleys etc.)

- Metal brackets for both Y axis and print heads

- Wires, drag chains and optical end-stops

Automatic Filament Changer

Modix’s IDEX can also be used as an automatic filament changer. When using the same filament on both print heads, the printer will be able to switch between the print heads automatically once one the printer detects a filament run-out.

Here are the benefits:

Get prints faster – One of the biggest challenges of 3D printing is the need to constantly monitor and maintain the printer. This can be especially frustrating when the machine has to sit idle overnight while waiting to be fed with a new filament spool. That’s where the Modix IDEX Filament Changer comes in. This clever technology allows the printer to switch out filament spools on its own, without having to pause its operation and wait. That means you can keep your printer running around the clock, without losing time on waiting for someone to service it.

Improved print quality – Not only does the Modix IDEX Filament Changer save you time, but it also helps to improve the quality of your prints. By not having to open the enclosure for service, the printer is able to maintain its chamber’s temperature, preventing the partly printed model from shrinking. This allows you to produce higher quality prints with fewer defects. If you want to take your 3D printing to the next level, be sure to check out the Modix IDEX add-on.

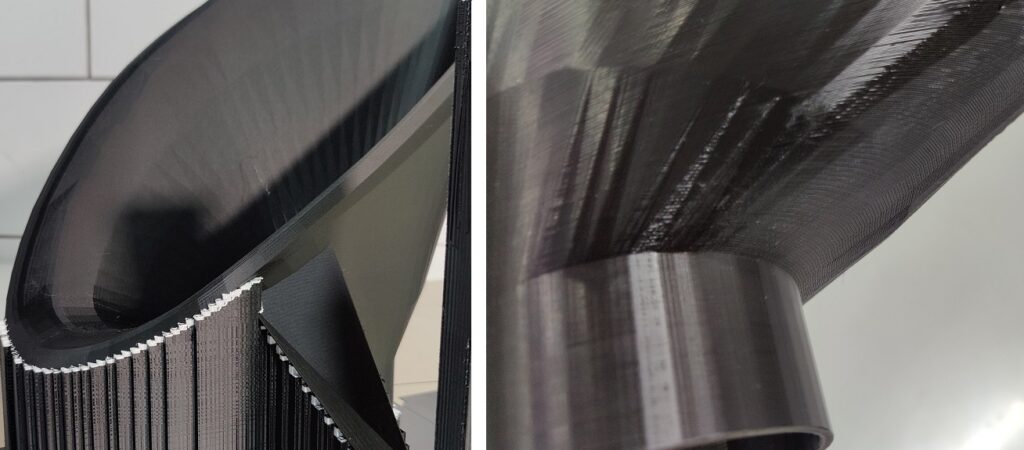

Griffin High-Flow Hotend

Griffin High-Flow Hotend is an optional add-on designed for customers who print large bulky objects and need to print fast. It is also an excellent choice for printing thick vase mode style objects since the single walled objects are stronger.

This add-on is provided with 80W heater and a thermistor. The new addition is now delivered with a mounting CNC made bracket. This mounting protects and stabilizes the long heatblock during printing. As a result it provides high print quality as vibrations are minimized during accelerations.

Includes:

Griffin HF Heat-block, 80W heater, PT-1000 Thermistor & 1mm nozzle

Modix BIG-180X V4 – The Ultimate Large-Format 3D Printer for Professionals

Unlock limitless possibilities with the Modix BIG-180X V4, a high-performance 3D printer machine designed for professionals who demand precision, automation, and an expansive build volume. Equipped with fully automated calibration, this best-in-class 3D printer ensures effortless operation while delivering exceptional print quality. Whether you're prototyping, manufacturing, or crafting large-scale designs, the BIG-180X V4 is the perfect tool to bring your vision to life.

Why Choose the Modix BIG-180X V4?

- Fully Automated Calibration – Enjoy hands-free, precision tuning with automatic bed leveling and nozzle calibration for flawless prints.

- Massive Build Volume – Create extra-large prints up to 1,800 x 600 x 600 mm, ideal for industrial-scale projects and detailed prototyping.

- Industrial-Grade Performance – Built with premium components, including Hiwin linear rails, a rigid aluminum frame, and a powerful dual-drive extruder, ensuring stability and durability.

- User-Friendly & Smart Interface – Features a responsive touchscreen, remote monitoring, and intuitive controls for seamless printing experiences.

- Multi-Material & High-Speed Printing – Print with PLA, ABS, PETG, carbon fiber, and more at high speeds, while maintaining precision and accuracy.

Designed for Professionals & Industrial Applications

The Modix BIG-180X V4 is built for engineers, manufacturers, and product designers who need a highly reliable, large-format 3D printer for professional applications. With its fully automated calibration system, users can focus on innovation and productivity while the printer ensures optimal precision with minimal intervention. Whether you're creating large prototypes, functional parts, or intricate industrial designs, this cutting-edge 3D printer guarantees efficiency, accuracy, and outstanding print quality.

Upgrade your production with the Modix BIG-180X V4—where automation, precision, and large-scale capabilities redefine professional 3D printing. 🚀

Shipping

Online orders above $99 across Australia** as well as Sydney metro orders above $49.95 are entitled to free standard shipping. We use a combination of different courier services for standard shipping depending on the destination and the size of the order. For standard shipping to Sydney Metro we generally use Australia Post, TNT, Toll or Sendle depending on product weight and size.

*Some remote regions or products may be ineligible for free shipping.

**Printers and certain accessories do not qualify for free shipping and freight will be charged at checkout

Orders under $99 will incur a flat rate subsidised shipping cost of $14.95.

Printers and certain accessories will incur a shipping charge of $39.95 for most areas*

*Some remote regions or products may incur a higher shipping charge for printers

Depending on the order size, express shipping is available at an extra cost. Express shipping service is provided by TNT Road Express or Australia Post Express.

- Click here for information about Australia Post Express shipping times.

- Click here for information about TNT Road Express shipping times.

Delivery options for large equipment (i.e Large / Industrial 3D Printers) and bulk trade orders may vary depending on the product & order size.

Products are shipped F.O.B. (Freight On Board) and become the sole property of the purchaser upon delivery to the specified shipping agent. For shipping damage, customers should file a claim to their carrier immediately. Any discrepancy, including wrong items or missing items, should be reported to Add labs within 48 hours.

Tracking my order

Customers can track their order by following the tracking link received via email once your order has been dispatched.

Returns & Refunds

If you have ordered the wrong product or changed your mind, we offer a 30 day return policy.

If you have received the wrong product or if there is a discrepancy with your order, please contact us within 48 hours of receiving the delivery.

Return Terms and Conditions

If you have ordered the wrong product or changed your mind, to be eligible for a return your item must be complete, unused and in the same condition that you received it. It must also be in the original packaging with no damage and suitable for re-sale as new. The value of our cost of shipping charges on the initial purchase delivery is non refundable. If you have not been charged a shipping fee for the order, the refund less the actual Add labs shipping cost will still apply.

To initiate a return, we require a receipt or proof of purchase. A “Return Authorization” number must be issued by Add labs prior to the return of any goods. Goods returned are to be referenced by this number, or they will not be accepted.

Returning items after 30 days is not permitted as your purchase is final and no returns will be accepted.

Accepted returns are to be sent to Add labs or the Distributor (if applicable) as advised by Add labs with freight to be prepaid by the customer. All returns must include trackable shipping and shipping insurance. We cannot guarantee that we will receive your returned item or that your item will arrive without damage.

Refunds (if applicable):

Once your returned item(s) is received and checked, we will send you an email to notify you that we have received your returned item. We will also notify you of the approval or rejection of your refund. Where the refund is approved, your refund will be processed, and a refund will automatically be applied to your credit card or original method of payment, within 14 days.

We abide Australian Consumer Guarantee Rights and Laws:

More Consumer Rights and Information can be viewed here.

Non-returnable items:

Samples, gift cards and software are non-returnable items.

Return Process:

If the manufacturer determines that the goods are faulty, please contact us at sales@addlabs.au. A Return Authority (RA) will be issued, and the goods should be shipped back in accordance with the "Return of Goods" section. Items identified as having a major fault within 14 days of receipt may qualify for a full refund.

Please label the carton with the RA number and please email us at sales@addlab.au with a tracking number to ensure we are aware of the return.

Manufacturer's Warranty:

The majority of items are accompanied by a 12-month manufacturer's warranty, subject to applicable terms and conditions.

Operators:

Operators (end-users) are required to possess a foundational understanding of or demonstrate a willingness to learn about the operation of these machines. This encompasses knowledge of computers, mechanical operations, software, materials, and other relevant aspects pertinent to the selected machine.

Expectations:

Manufacturers anticipate that operators will assemble and maintain their machines, including the replacement of parts such as consumables, electronics, and other components. Operators are also expected to become proficient in the requisite software and firmware to operate the machine effectively. It is imperative to contact the manufacturer with any issues to ascertain whether the item is faulty.

Maintenance:

Regular maintenance is essential for these machines, with intervals varying based on specific requirements. Operators are responsible for performing maintenance themselves or securing the services of a qualified technician. Neglecting maintenance may result in damage and void the manufacturer's warranty.

Guarantee under Australian Consumer Law (ACL):

Operators are entitled to consumer guarantees as outlined by the Australian Consumer Law (ACL). In instances where an item exhibits a major fault, operators are entitled to request a replacement or refund. For minor faults, the item may be repaired using new or used parts, or it may be replaced. Please refer to the "Return of Goods" section for additional information.

Initial Inspection:

Upon receipt of the item, please conduct a thorough inspection and document any damage to the parcel. If you suspect the item has sustained damage during transit, contact us immediately. During the unpacking and assembly process, consult the manufacturer's instructions and reach out to them if any issues arise. Problems caused by incorrect assembly may not be covered under the manufacturer's warranty.

Slicers and Software:

Most manufacturers utilize open-source or community-based slicers and software. Operators are expected to attain proficiency in this software. ncorrect profile selection or software modifications by the operator can result in machine damage and may not be covered by the warranty. Additionally, using third-party files (3MF, STL, G-Code, etc.) can cause issues that may not be covered. Firmware updates are customary; however, improperly applied firmware can "brick" a machine, which may not be covered under warranty. SD card corruption can also occur, and third-party or customer firmware may not be covered.

Consumable Items:

Consumables include, but are not limited to, hotends, thermistors, nozzles, fans, belts, wheels, drivers, mainboards, SD cards, AMS (Automatic Material System), PTFE tubes, FEP, PEI, LCD screens, lasers, beds, vats, sensors, and materials. These parts generally have a 3-month manufacturer warranty.

End of Life (EOL):

Given the rapid advancements in technology, machines are expected to have a lifespan of up to 2 years before reaching EOL. Parts may become unavailable after 2 years from the product's release date.

Materials:

Material consistency can vary between manufacturers and batches. Operators are expected to test materials and adjust profiles accordingly. Failure to use the correct profile may result in faults that are not covered by the warranty.

"Wet Materials" do occur, though not that often.

Please note "wet filament", may not be considered warrant-able as drying materials is part of the printing process.

Satisfaction:

If you are dissatisfied with any item received from us, you may be entitled to return it in accordance with the "Return of Goods" section.

Contact Us

Address:

Consultations at our Oran Park hub by appointment only

suite 208/351 Oran Park Dr

Oran Park NSW 2570 Australia

Phone: +61 2 9161 4164

Email: sales@addlabs.au

Browse

Subscribe

Join our mailing list for the latest updates and promotions.

By subscribing, you agree to our Privacy Policy and consent to receive updates from us.

- Choosing a selection results in a full page refresh.

- Opens in a new window.